Click

Share the files: Upload CAD, prints, or even a quick sketch. We’ll confirm feasibility, materials, and schedule.

Precision machining & mechatronics

Bringing the future to the present. Est. 2018

Integrated engineering + manufacturing

By the numbers

Most repeat work starts within a business day. Below are a few stats about what we're up to.

Trusted by

Our parts & software power everything from your favorite bars and clubs, to defense manufactures protecting the nation and its people.

See the full client stories GSG Mfg LLC

GSG Mfg LLC

Player Aerospace

Player Aerospace GSG Mfg LLC

GSG Mfg LLC

Player Aerospace

Player Aerospace GSG Mfg LLC

GSG Mfg LLC

Player Aerospace

Player Aerospace GSG Mfg LLC

GSG Mfg LLC

Player Aerospace

Player Aerospace GSG Mfg LLC

GSG Mfg LLC

GSG Mfg LLC

GSG Mfg LLC

Player Aerospace

Player Aerospace GSG Mfg LLC

GSG Mfg LLC

Player Aerospace

Player Aerospace GSG Mfg LLC

GSG Mfg LLC

Player Aerospace

Player Aerospace GSG Mfg LLC

GSG Mfg LLC

Player Aerospace

Player Aerospace GSG Mfg LLC

GSG Mfg LLC

Share the files: Upload CAD, prints, or even a quick sketch. We’ll confirm feasibility, materials, and schedule.

We machine in-house: Programming, machining, light printing, and inspection all happen in the same Seattle shop.

Review & iterate: You get photos, measurement notes, and parts packed for the next round of testing.

4-axis milling in aluminum, stainless, brass, titanium, and engineering plastics. Setups stay ready for quick reruns.

Lathe Turning for bushings, shafts, and housings with hand-fit checks before shipping.

Carbon-filled nylon and engineering-grade plastics for tooling, fixtures, and workholding.

Lightweight firmware, scripts, and automation to get business problems solved fast.

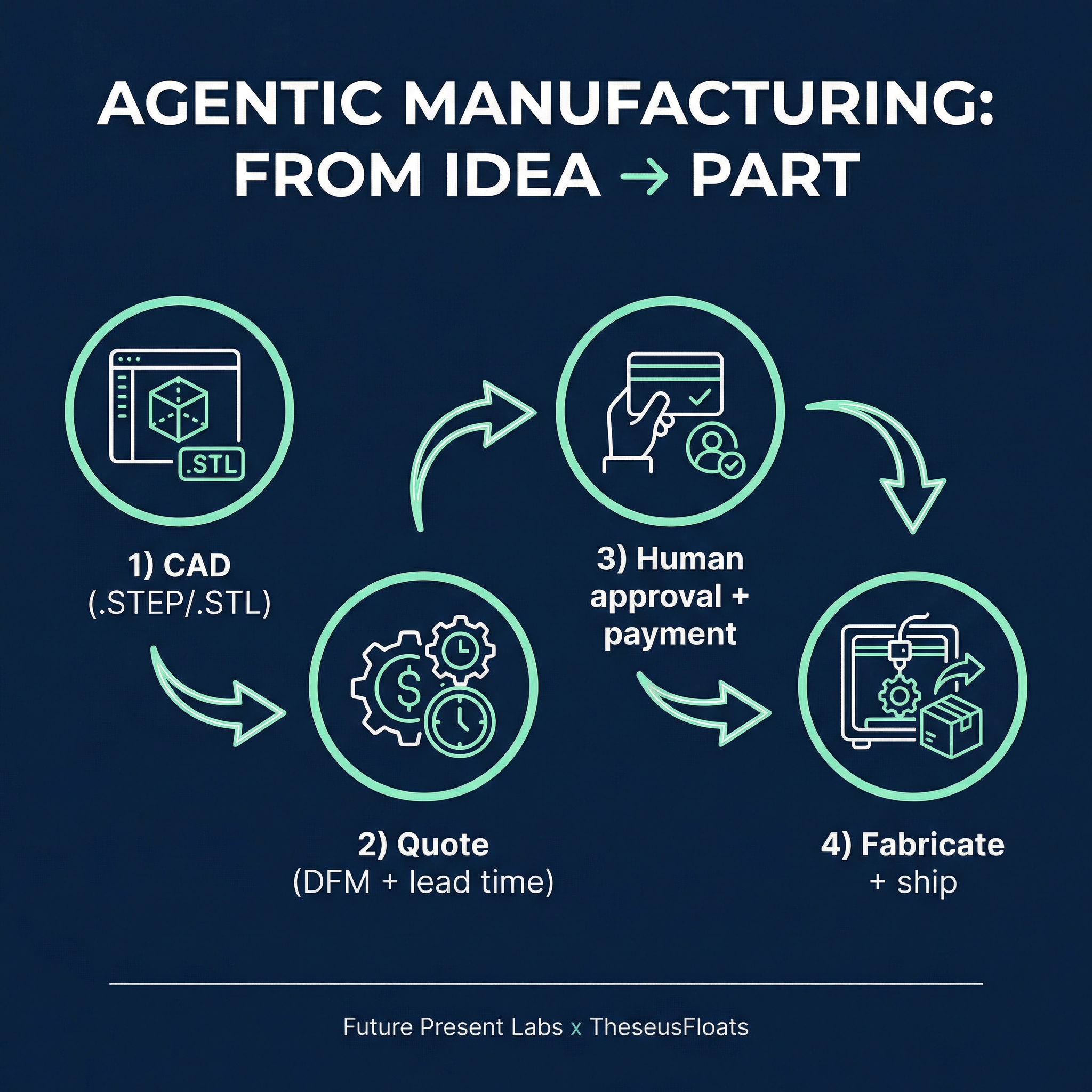

Future Present Labs is building the physical infrastructure for agentic manufacturing. From CAD generation to parts on your doorstep — we close the loop between digital intent and physical reality.

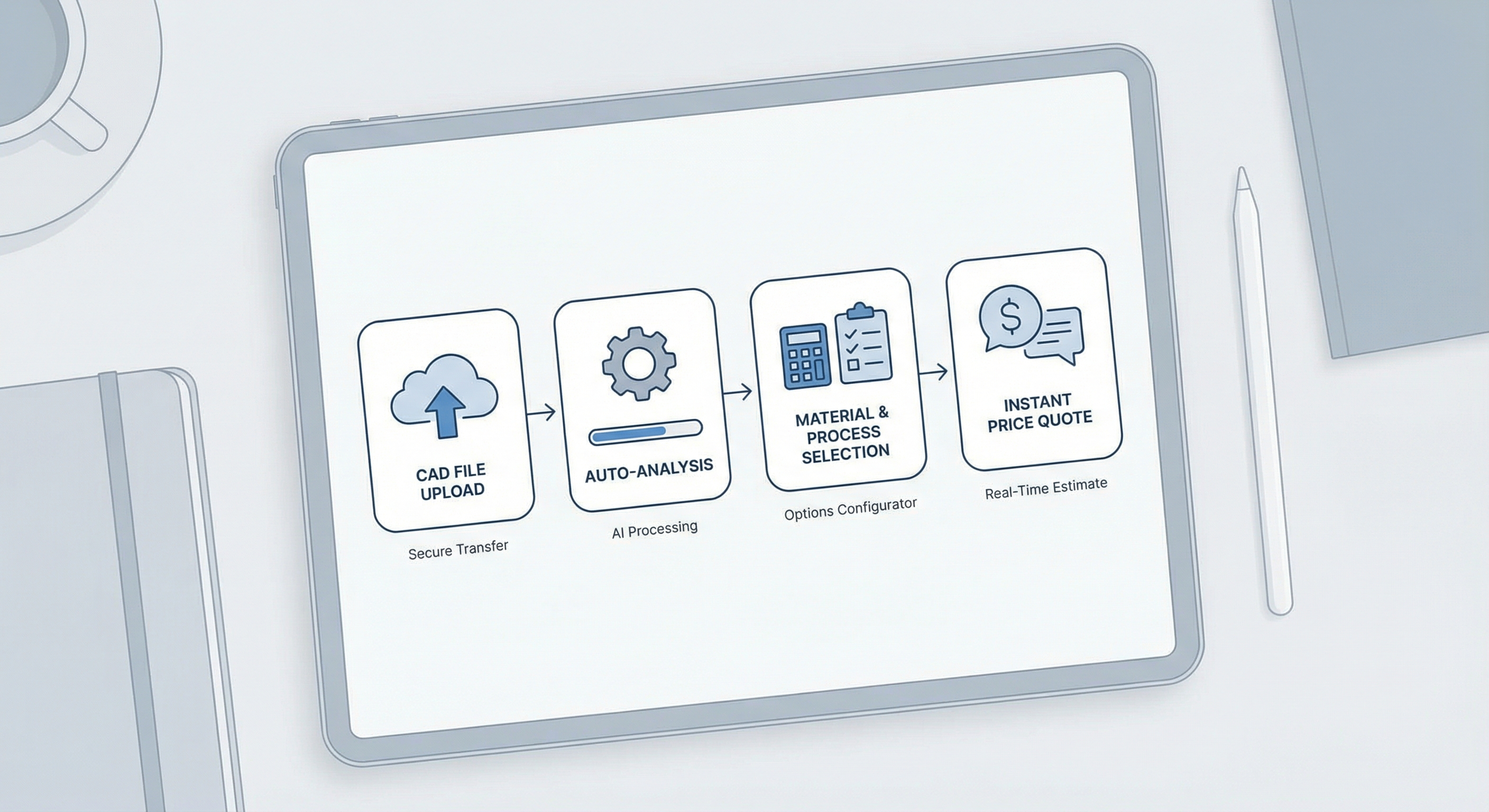

Upload your CAD files and receive transparent pricing within hours. No more waiting days for machine shop quotes. Know your costs fast and keep your project moving.

Upload CAD, prints, or even a napkin sketch. Our quoting flow calls out risks, suggests materials, and books the next open slot on the mill or lathe.

Prefer to walk through it on a call? Use the contact form below.

Tell us about your project. Whether you have a CAD file ready for machining or a rough concept that needs guidance, we’re here to help.