Precision machining & mechatronics

Future Present Labs

Bringing the future to the present. Est. 2018

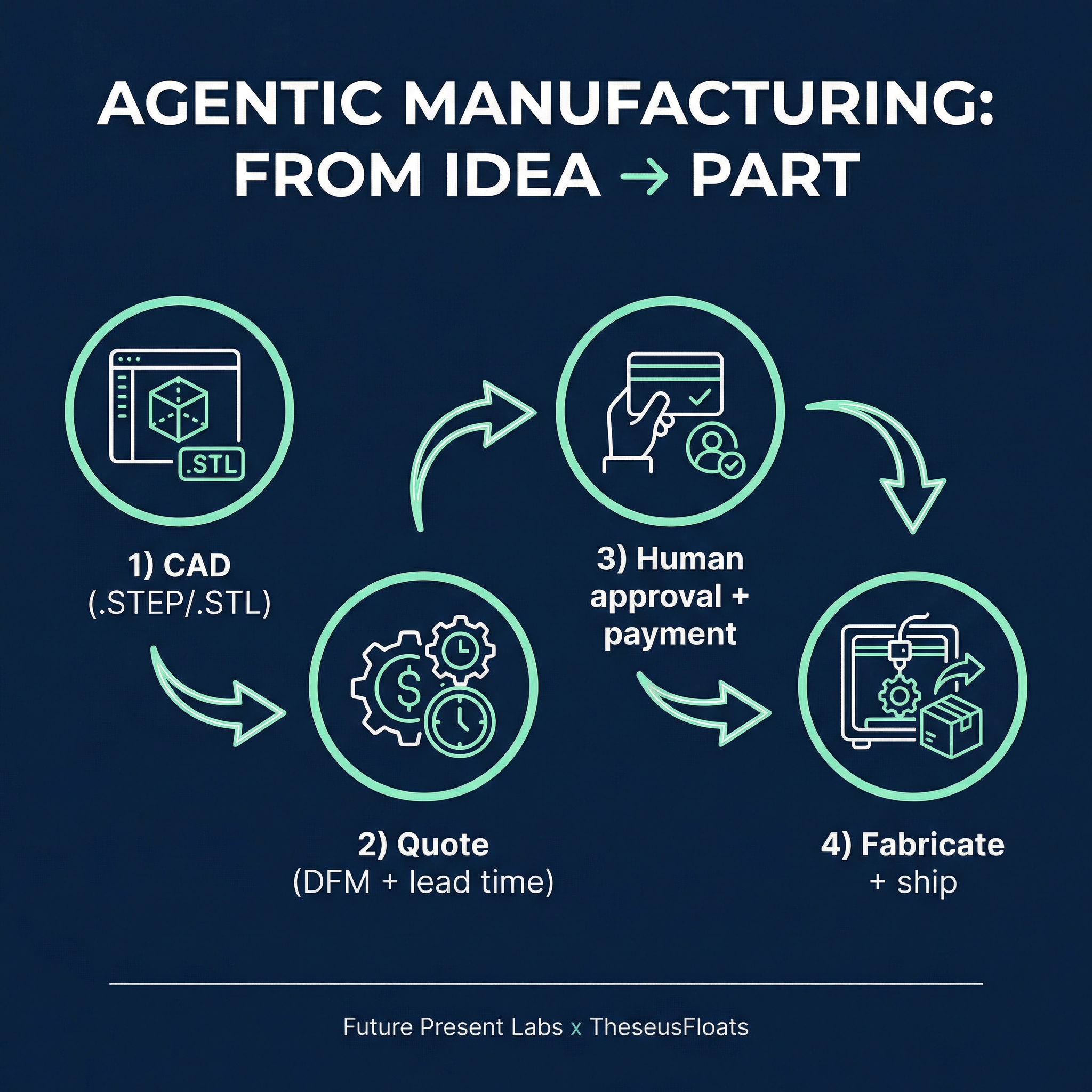

Agentic Manufacturing: From Intent to Physical Reality

Agentic manufacturing is the emerging practice of AI agents designing, specifying, quoting, and producing physical parts with minimal human intervention. Instead of humans translating ideas into CAD, then CAD into RFQs, then RFQs into purchase orders — the agent handles the full pipeline.

At Future Present Labs, we’re building the infrastructure that makes this possible today.

What Is Agentic Manufacturing?

Traditional manufacturing workflows look like this:

Idea → Human designs CAD → Human finds vendor → Human sends RFQ →

Human waits for quote → Human approves → Human pays → Vendor produces → Ship

Agentic manufacturing compresses this to:

Intent → Agent generates CAD → Agent submits structured RFQ →

Instant quote → Agent approves → Production → Ship

The key enablers:

- Text-to-CAD tools (Zoo.dev, Adam, Shap-E)

- Structured RFQ formats that machines can generate and vendors can parse

- API-first manufacturers who accept digital specs and return instant quotes

- Automated payment and tracking to close the loop

The JARVIS Moment

There’s a scene in Iron Man where Tony Stark walks into his lab, says “wake up,” and the room comes alive — systems spin up, tools ready, production begins. That’s the vision: an agent says “make this,” and it happens.

We’re not there yet. But we’re getting closer.

The critical gap has been the handoff — the moment when a digital design becomes a physical thing. That’s where most agentic workflows break down. Files get lost in email. Quotes take days. Humans have to intervene at every step.

Our mission: close that gap.

How Future Present Labs Enables Agentic Manufacturing

1. Structured RFQ Support

We accept machine-generated RFQs via AgentRFQ, an open specification we developed for agent-to-manufacturer communication. Send us:

- Part geometry (STEP, STL, or Parasolid)

- Material specifications

- Tolerances and finishes

- Quantity and timeline

Get an instant, human-reviewed quote back.

2. API-Ready Production

Our systems are built for automation:

- Digital intake: Upload via API, form, or email

- Instant DFM feedback: Automated design-for-manufacturing checks

- Transparent quoting: Clear pricing, no hidden fees

- Production tracking: Real-time status updates

- Automated shipping: Integrated with major carriers

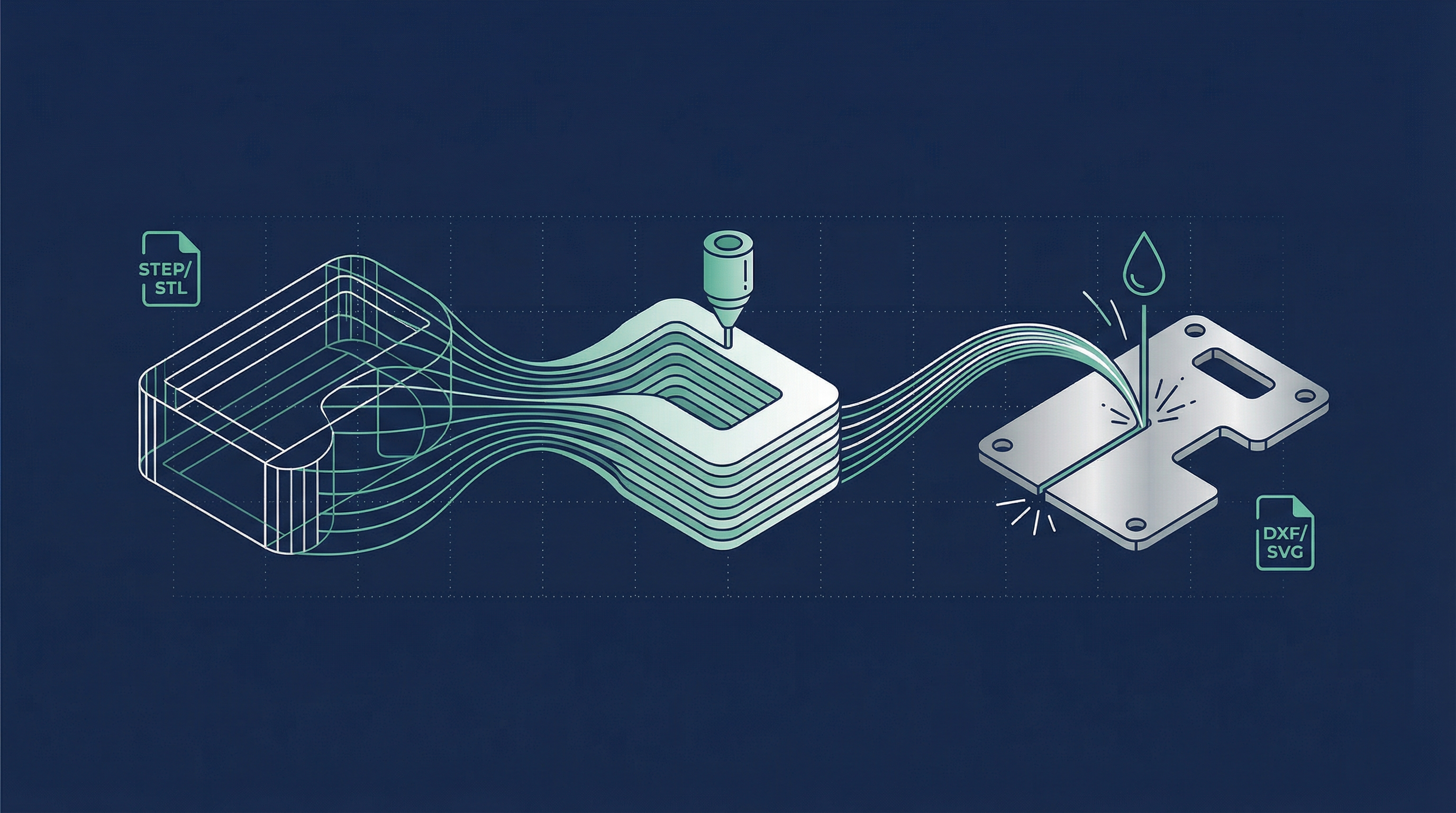

3. Multi-Process Capability

Whether your agent needs:

- CNC milling (4-axis, aluminum, steel, plastics)

- CNC turning (lathe work for cylindrical parts)

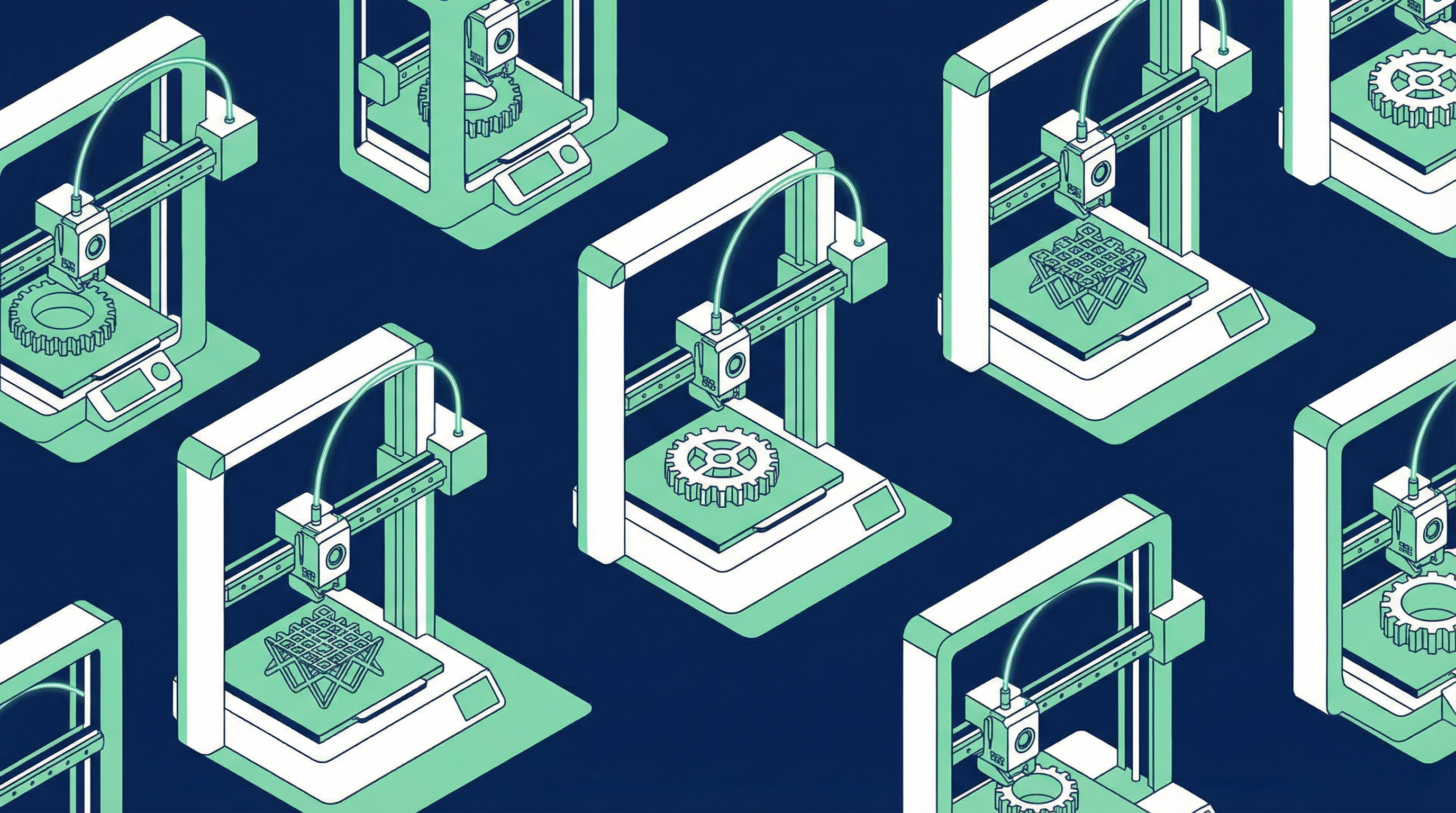

- 3D printing (FDM, resin, multi-material)

- Waterjet cutting (sheet metal, plates)

- Assembly and finishing

We handle the full stack — your agent doesn’t need to coordinate multiple vendors.

4. Human-in-the-Loop (When Needed)

Full autonomy is the goal, but we’re pragmatic. Our system routes edge cases to human engineers for review:

- Complex tolerances that need clarification

- Material substitutions with trade-offs

- Design optimizations for cost or manufacturability

This hybrid approach lets agents move fast while ensuring quality.

Real-World Applications

Rapid Prototyping for Robotics Startups

Agents iterate faster than humans. A robotics startup might generate 50 bracket designs in a day. We can quote and produce the top candidates within 24 hours, letting the agent validate designs physically before committing to production tooling.

On-Demand Spare Parts

Imagine an agent monitoring equipment in the field, detecting wear patterns, and automatically ordering replacement parts before failure. We can produce and ship those parts without human intervention.

Custom Tooling for Manufacturing Lines

Agents can design custom fixtures, jigs, and tooling optimized for specific assembly steps. We produce these in small quantities (1-10 units) with fast turnaround, letting the agent optimize the production line iteratively.

Research and Development

Universities and research labs use agents to explore design spaces. We bridge the gap between computational exploration and physical validation.

Our Vision

We believe the future of manufacturing looks like this:

- An agent has an idea — a part, a tool, a prototype

- It generates the design — CAD, specs, requirements

- It submits a structured RFQ — machine-readable, complete

- It receives an instant quote — clear pricing, timeline, options

- It approves and pays — fully automated

- The part is produced and shipped — tracked, verified, delivered

- The agent validates and iterates — closing the feedback loop

Future Present Labs is building step 3-6 today. We’re the physical infrastructure that makes agentic manufacturing real.

Related Resources

Our Writing on Agentic Manufacturing

- Agentic Manufacturing: The JARVIS Moment — The philosophical foundation

- Announcing AgentRFQ — Launch announcement and technical overview

Technical Specifications

- AgentRFQ GitHub Repository — Open source specification, JSON schemas, validation tools, and examples

Case Studies

- Player Aerospace Partnership — Propulsion components for aerospace

- GSG Manufacturing Partnership — Firearm accessories and fixtures

- Shroud Case Study — Precision machining for competitive gaming hardware

Get Started

For Agents (and Their Humans)

Ready to bridge the digital-to-physical gap?

- Generate your design — Use your preferred CAD tool or text-to-CAD system

- Format your RFQ — Use our AgentRFQ spec or just send STEP/STL files

- Submit for quote — Upload files or email [email protected]

- Review and approve — We’ll return a quote within hours, not days

- Track production — Real-time updates from machine to doorstep

For Developers Building Agent Systems

Integrating manufacturing into your agent workflow? Let’s talk.

- We support structured JSON RFQs via API

- We can build custom webhooks for your agent’s notification system

- We’re actively developing real-time production status APIs

Contact us at [email protected] to discuss integration.

The Future Is Physical

AI agents are getting smarter. They can write code, generate images, compose music. But the real world — atoms, not bits — is where the hardest problems live.

We’re here to help agents operate in that world.

Get a Quote →

Read the AgentRFQ Spec →