Precision machining & mechatronics

Future Present Labs

Bringing the future to the present. Est. 2018

Get a Quote for CNC Machining & 3D Printing in Seattle

Need parts made? Future Present Labs is a Seattle machine shop offering fast, transparent quotes and quick turnaround on prototypes and production runs.

Upload your CAD files and receive detailed pricing within hours—not days. No hidden fees, no surprises.

The Problem with Traditional Machine Shop Quotes

If you’ve worked with traditional shops, you know the frustrating cycle:

- Email your files and wait…

- Follow up when you don’t hear back

- Answer questions about tolerances, materials, quantities

- Wait more while they manually calculate

- Get an unclear quote with vague line items

- Start over when the price doesn’t work

Total time: 3-7 days. That’s a week of delay before production even starts.

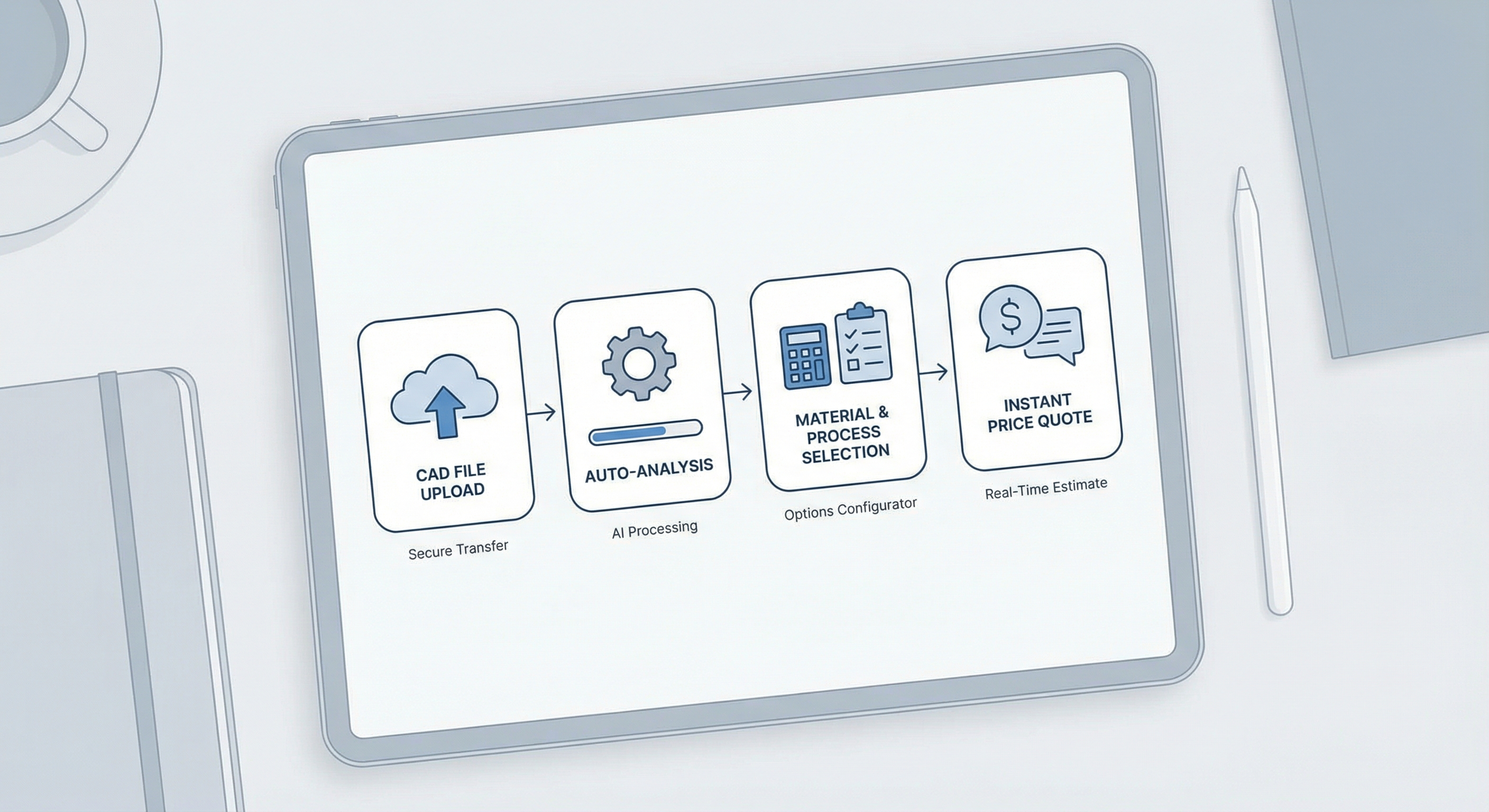

Our Quote Process—Pricing in Hours

We’ve streamlined our process to get you answers quickly:

1. Upload Your Files

Send your CAD files through our quote form, email, or file transfer. We accept:

- STEP (.step, .stp) — Preferred for CNC machining

- STL (.stl) — For 3D printing

- Parasolid (.x_t, .x_b) — For complex geometry

- SolidWorks (.sldprt, .sldasm) — Native format support

- Fusion 360 — Direct export compatibility

- AutoCAD DXF — For 2D waterjet/laser cutting

Don’t have CAD files? Send a sketch, photo, or description. Our engineers can help develop manufacturable designs from your concepts.

2. Automated Design Review

We automatically analyze your files for:

- Manufacturability — Can this be made with standard processes?

- Material fit — What alloys or plastics suit your needs?

- Tolerances — Are your specifications realistic and cost-effective?

- Setup requirements — How many operations are needed?

- Risk factors — Thin walls, deep pockets, tight tolerances

This design-for-manufacturing (DFM) check happens within minutes.

3. Transparent Pricing

Receive a detailed breakdown:

- Material costs — Based on current pricing

- Machine time — Accurate hour estimates

- Setup fees — One-time per-batch costs

- Post-processing — Finishing, coating, assembly

- Shipping — Options from economy to overnight

No hidden fees. No surprises. The price you see is the price you pay.

4. Engineer Review (When Needed)

For complex parts, a human engineer reviews the quote to ensure accuracy. This gives you speed without sacrificing precision.

Most quotes are returned within 2-4 hours during business hours. Complex assemblies may take up to 24 hours.

What Affects Your Quote

Understanding these factors helps you design for cost-effective manufacturing:

Material Selection

| Material | Best For | Relative Cost |

|---|---|---|

| Aluminum 6061 | General purpose, prototyping | $ |

| Aluminum 7075 | High strength, aerospace | $$ |

| Stainless 304 | Corrosion resistance | $$ |

| Stainless 316 | Marine/chemical environments | $$$ |

| Steel 4140 | Strength, wear resistance | $$ |

| Brass 360 | Electrical, decorative | $$ |

| ABS (3D print) | Functional prototyping | $ |

| PETG (3D print) | Durability, ease of print | $ |

| Resin (SLA) | Fine detail, smooth finish | $$ |

Geometry Complexity

- Simple parts (brackets, plates): Lower cost, faster quotes

- Moderate complexity (housings, mounts): Standard pricing

- Complex geometry (organic shapes, internal features): Higher setup, longer machine time

Tolerances

- Standard tolerances (±0.005"): No additional cost

- Tight tolerances (±0.001"): May require additional operations

- Very tight tolerances (±0.0005"): Specialized tooling, higher cost

Quantity

- Prototypes (1-10): Higher per-part cost, fastest turnaround

- Low volume (10-100): Economies of scale begin

- Production (100+): Significant per-part savings

Surface Finish

- As-machined: Fastest, lowest cost

- Bead blast: Uniform matte appearance

- Anodize: Corrosion protection, color options

- Powder coat: Durable, cosmetic finish

Real Projects We’ve Delivered

Robotics Startup: 48-Hour Iteration Cycle

A Seattle robotics company needed to iterate quickly on bracket designs:

- Morning: Upload new bracket design

- Midday: Receive quote, approve production

- Next day: Parts in hand, test fit

- Repeat: New iteration same day

Result: 12 design iterations in 2 weeks vs. 2 iterations with their previous vendor.

Aerospace: Precision Parts in 5 Days

Player Aerospace needed propulsion components with tight tolerances:

- Day 1: STEP files uploaded, quote received in 3 hours

- Day 2: Design review call, minor tolerance adjustment

- Day 3-4: Parts machined

- Day 5: Parts delivered, inspected, approved

Result: Critical path component delivered ahead of schedule.

Event Venue: Custom Fixtures

C7 Event Venue needed custom lighting fixtures for a grand opening:

- Quote: Received same day

- Production: 3-day turnaround

- Installation: Completed day before event

Result: Opening night went off without a hitch.

Turnaround Times

Fast quotes matched by fast production:

| Service | Standard Delivery | Rush Service |

|---|---|---|

| 3D Printing (FDM) | 1-2 days | Same day |

| 3D Printing (Resin) | 2-3 days | Next day |

| CNC Milling | 3-5 days | 2 days |

| CNC Turning | 3-5 days | 2 days |

| Waterjet Cutting | 2-3 days | Next day |

| Assembly | +1-2 days | Available |

Rush service available for urgent deadlines. Contact us for rush pricing.

Our Capabilities

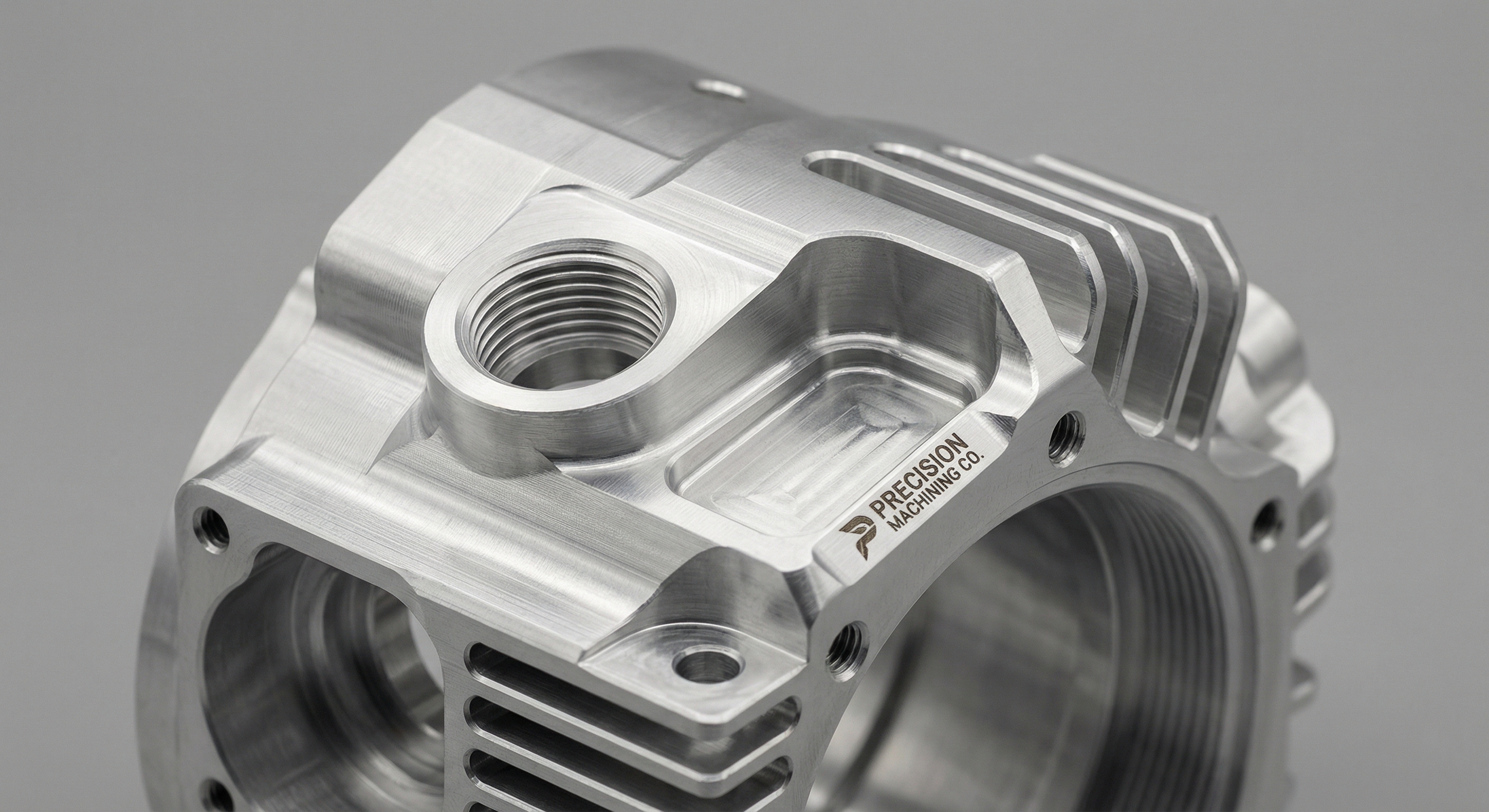

CNC Machining

- 4-axis CNC milling for complex geometry and precision parts

- CNC lathe for cylindrical and turned components

- Materials: Aluminum, steel, stainless steel, brass, engineering plastics

- Tolerances: Down to ±0.001" (0.025mm) standard

- Quantities: From 1 prototype to 1,000+ production parts

3D Printing

- FDM printing for fast, functional prototypes

- Resin (SLA) printing for fine detail and smooth surfaces

- Materials: PLA, PETG, ABS, ASA, Nylon, engineering resins

- Build volume: Up to 300mm x 300mm x 400mm (11.8" x 11.8" x 15.7")

- Layer resolution: 0.1mm to 0.3mm

Additional Services

- Assembly for multi-part designs and sub-assemblies

- Finishing: Bead blast, anodizing, powder coating, painting

- Hardware installation: Threaded inserts, Helicoils, PEM fasteners

- Packaging: Custom packaging for your requirements

How to Get a Quote

Option 1: Upload Files Online (Fastest)

Use our quote form to upload your files. Include:

- CAD files or technical drawings

- Material preferences (or ask for suggestions)

- Quantity needed

- Timeline

- Special requirements (tolerances, finishes, certifications)

Option 2: Email Your Project

Send files to [email protected] with project details. We’ll reply with pricing within hours.

Option 3: Schedule a Call

For complex projects, email us to schedule a consultation with our engineers.

Frequently Asked Questions

Q: How accurate is your quoting?

A: Our automated quotes are typically within 10% of final cost. For complex parts, we may follow up with questions to ensure accuracy.

Q: What if I don’t have CAD files?

A: Send us sketches, photos, or detailed descriptions. We can help develop manufacturable designs from your concepts.

Q: Can you handle production volumes?

A: Yes. While we specialize in prototypes and low-volume orders (1-1,000 pieces), we can scale to higher volumes through our partner network.

Q: Do you offer design services?

A: We provide DFM feedback and minor design optimizations as part of our quoting process. For full design services, we can refer you to partners.

Q: What if the quote is outside my budget?

A: We’ll work with you to identify cost-reduction opportunities—simplifying geometry, changing materials, adjusting tolerances, or modifying quantities.

Ready to Get Started?

Stop waiting days for manufacturing quotes. Get transparent pricing fast and keep your project moving.

Or email us to discuss your project.